Falls are one of the leading causes of serious work-related injuries and deaths. Recognizing the critical nature of this hazard, the Occupational Safety and Health Administration (OSHA) has established comprehensive guidelines and regulations to mitigate the risks associated with working at elevated heights. Understanding and implementing these fall protection measures is essential for safeguarding workers' well-being across various industries.

Understanding Fall Protection

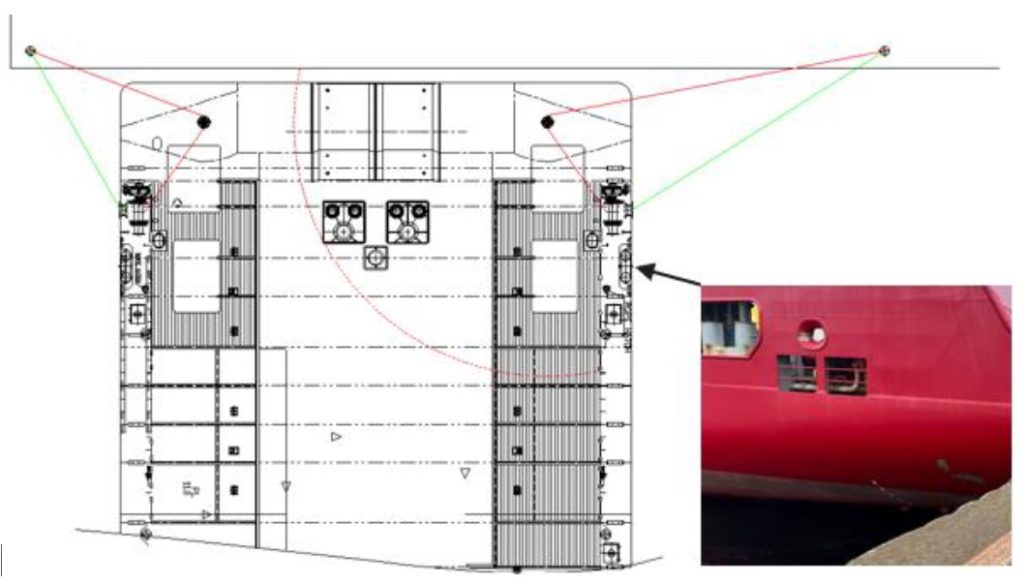

Fall protection encompasses a range of practices designed to prevent workers from falling off overhead platforms, elevated workstations, or into holes in the floor and walls. OSHA mandates fall protection at specific elevations across different industries: four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry, and eight feet in longshoring operations. Additionally, regardless of height, fall protection is required when working over dangerous equipment and machinery.

Key Measures to Reduce Falls

Employers must create a safe working environment by incorporating several protective measures:

- Guarding Floor Holes: Every floor hole into which a worker can accidentally walk must be guarded using railings, toe-boards, or floor hole covers.

- Guard Rails and Toe-Boards: These should be installed around every elevated open-sided platform, floor, or runway to prevent accidental falls.

- Protective Barriers: Regardless of height, if there is a risk of falling into or onto dangerous machines or equipment, guardrails and toe-boards must be installed to avert potential injuries.

- Additional Fall Protection Tools: Depending on the job, other measures such as safety harnesses and lines, safety nets, stair railings, and handrails may be necessary.

Employer Responsibilities

OSHA requires employers to adhere to several critical responsibilities to ensure fall protection:

- Provide Safe Working Conditions: Employers must ensure that working conditions are free of known hazards.

- Maintain Clean and Dry Floors: Keeping floors in work areas clean and dry, as far as possible, reduces the risk of slips and falls.

- Personal Protective Equipment (PPE): Employers are responsible for selecting and providing the necessary PPE at no cost to workers.

- Training: Workers must be trained about job hazards in a language they understand, enabling them to recognize and avoid potential fall hazards.

Industry-Specific Standards

Fall protection standards vary across industries. For the construction industry, specific OSHA standards address various aspects of fall protection, including the use of scaffolds, ladders, and safety nets. For non-construction activities, general industry and maritime standards outline the necessary fall protection measures. Employers should familiarize themselves with these standards to ensure compliance and enhance workplace safety.

Resources and Compliance

OSHA provides a wealth of resources to aid employers and workers in understanding and implementing fall protection measures. These include publications, fact sheets, compliance assistance materials, and training programs. Participating in initiatives like the National Safety Stand-Down, an annual event to raise awareness about fall hazards, can further reinforce a culture of safety.

In conclusion, fall protection is a critical component of workplace safety. By adhering to OSHA's regulations and implementing comprehensive fall protection measures, employers can significantly reduce the risk of falls and ensure a safer working environment for all employees. For more detailed information and resources on fall protection, visit the OSHA Fall Protection page.